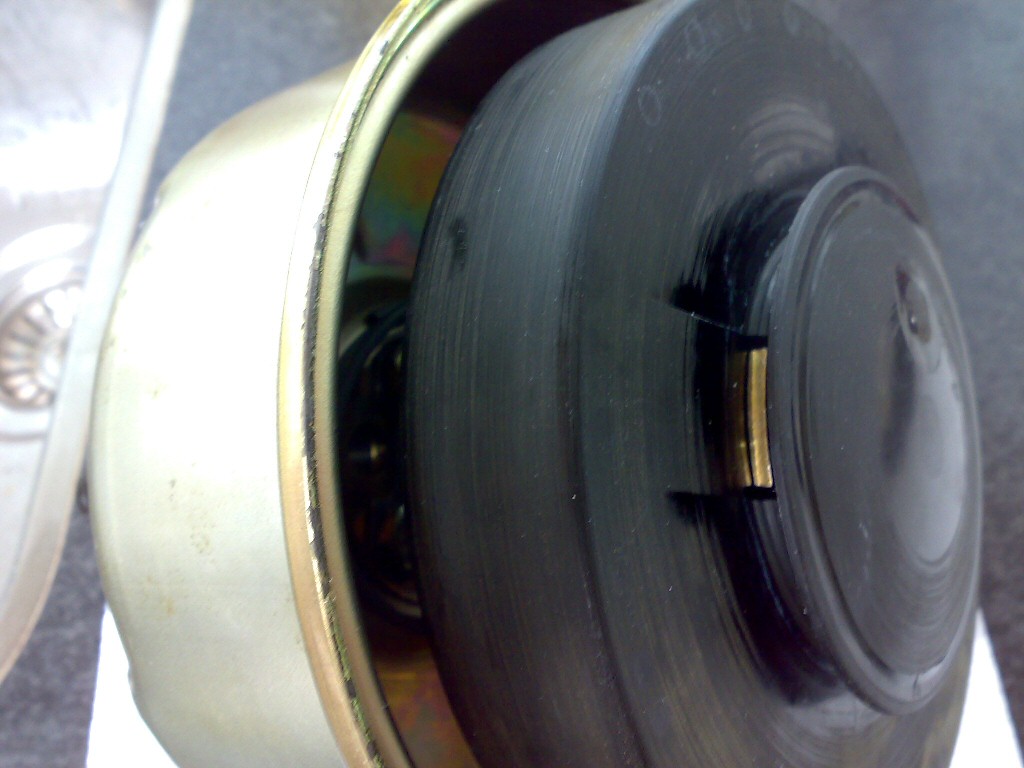

Lockheed brake servo before dismantling

Images of the revision of a Lockheed brake servo

Lockheed brake servo before dismantling

Air valve

Air valve cover removed (5 screws)

Membrane removed

Reaction piston retaining plate removed (3 screws).

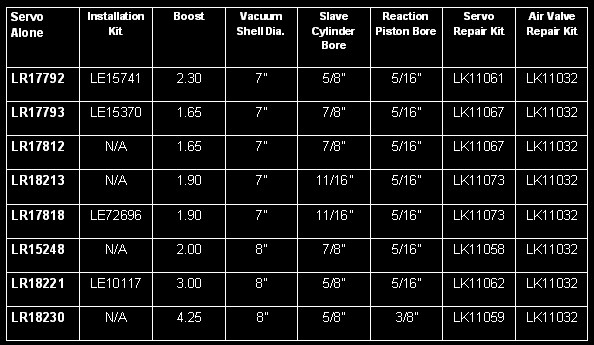

For identification of the servo the reaction piston can be measured

If it's 3/8" you have a LR18230 with a boost factor of 4.25,

which is not suitable for a spitfire but may fit perfect on a Rover P4 ;)

For all other types this should be 5/16"

For removal of the reaction piston you can best leave the servo

mounted in your braking system, remove all parts as mentioned above

and press the brakes gently. The reaction piston will be pushed out by the brake fluid.

If it's stuck be careful otherwise you will shoot it away if it suddenly releases!

Removal of back cover, rubber bellow visible

Rubber bellow gently removed, securing clamp visible

When pressing down the return spring the clamp can be taken out (should almost fall out)

Inside of the vacuum part, one way air valve visible

After removal of the housing (3 bolts), the backup guide,

seal and seal tensioner and spring the circlip retainer becomes reachable

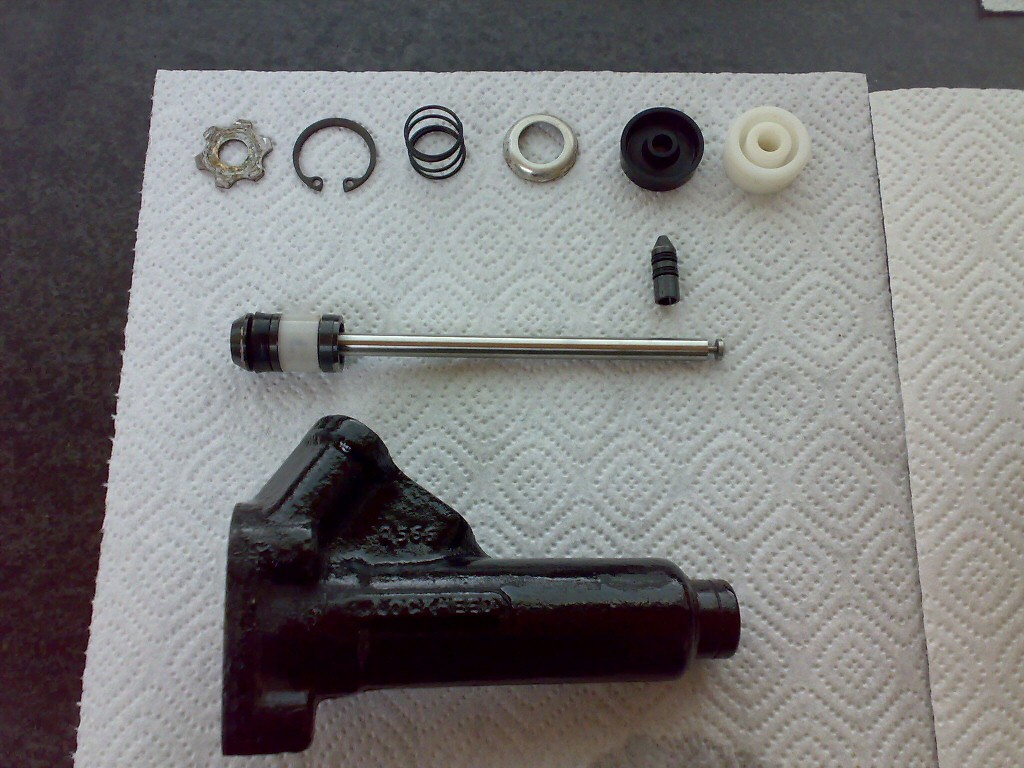

The parts in order of removal

Totally Right, the white part guides the piston rod

Seal which prevents brake fluid from entering the vacuum part

Washer which presses the seal against the guide

Spring to hold the washer and seal in place

Circlip ring to retain the piston

Left the washer behind the circlip

Bottom, the empty housing

This is what storage does to brake parts

I had the brake servo for some years before I mounted it

Unfortunately it had been filled with brake fluid by it's previous owner

and i stored it without totally flushing it out or filling it totally

Slave cylinder and reaction piston

The size of the slave cylinder can be measured to identify the servo

In my case the slave cylinder is 11/16"making it the LR17818

It has a boost ratio of 1.9 ideal for a Spitfire

Shell removed to thoroughly clean the piston

I started rebuilding the servo because the brakes hanged on for a few more seconds

after I had pressed the brake pedal

This is probably why. In the top of the air-valve there should be a spring to define

its standard position. I noticed this spring was missing, making the

return stroke only rely on vacuum being build up on one side.

Adding the spring results in more direct valve operation.

The dismantled air valve

The spring in place

All internal parts ready for reassembly

The reaction piston back in place

All components to be fitted again

Work in progress

Big return spring, plunger, bellow and back cover

Air valve and retaining ring

Reassembled

Reassembled hoping it will work...

The list of Remote Brake Servo's from Lockheed with their sizes and revision kits